more than 22 years of experience

We have coated hundreds of millions of parts since 1998. The experience gained allows us to manage with precision any mass serial production just as a piece production. The technology of cataphoresis helps the automotive industry, and it is now being discovered by companies in construction, electrical engineering and furniture production.

24/7 operations for you!

We use two independent coating lines. As a result, we are able to ensure operation 24/7 operations and be a strong partner for you, helpings you keep your customers satisfied. Clients work with us thanks to the high quality of our production and also thanks to the possibility to combine coating with sheet metal working, sheet metal stamping and subsequent assembly. These are benefits that save our clients time and further costs during actual production.

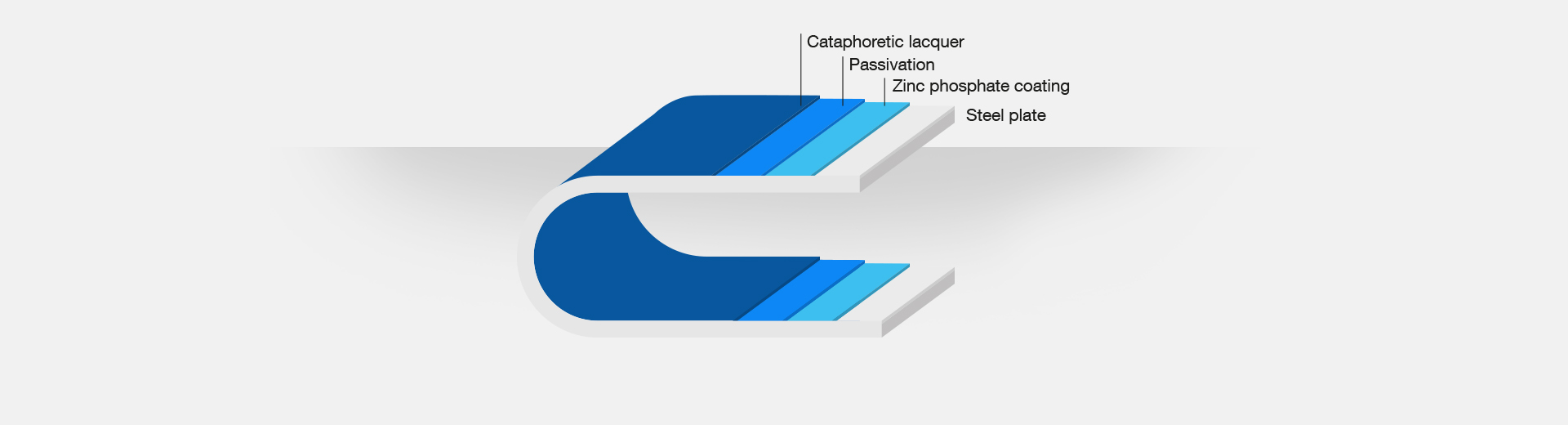

We apply eco-friendly organic films based on epoxy resin to the surface of the material. We apply a black film which serves as the basic anticorrosion layer, but it is not UV resistant and will turn grey over time. Sometimes this can be desirable. However, if you want to achieve the highest surface protection and colour fastness, we recommend to apply another protective layer to the used materials by powder coating.

We have two different plants for the finishing of your products - Frýdlant and Humpolec. In both plants we ensure anticorrosion tests for you in accredited laboratories.