The strength of Lakum consists in the combination of our metal components press shop, sheet metal processing and a wide range of surface treatment possibilities. For this reason, we can supply you with complete assemblies of products, which enables you to save on logistics costs and gives you the assurance that a single supplier is maintaining the high quality of work performed.

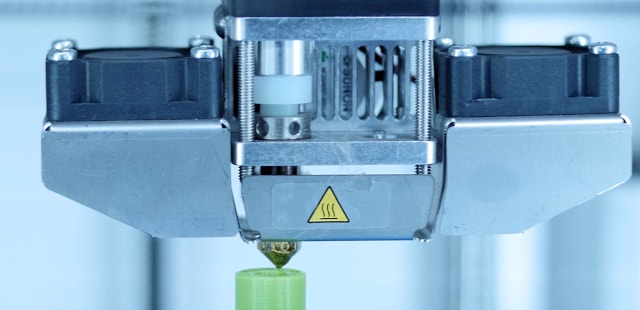

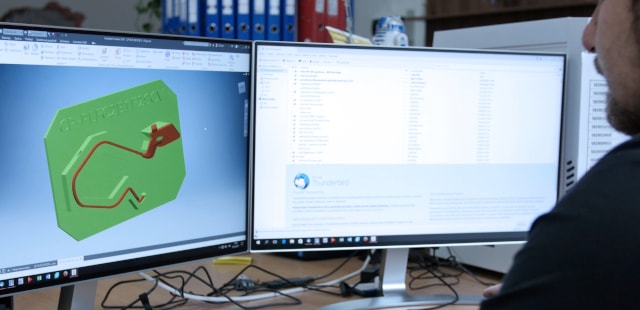

We use 3D printing for the design and production of prototypes in single units when creating shaping, bending jigs and control templates. We cooperate on 3D printing with a number of universities and suppliers with many years of experience. This cooperation allows us to print from a wide range of materials from plastic to metal for you.

We will help you to develop a prototype in the preparatory phase. Our best employees will work on the development and subsequent manufacture of prototypes and will employ their lifetime of know-how in this. We can react quickly to changes in the product design because during production of a prototype we do not always use just conventional shaping tools, but jigs that we are capable of making ourselves.

We specialise in the production of components with complicated shapes in medium production runs. We can employ our more than twenty years of experience in close cooperation with your designers, with whom we create the ideal design for the components. We optimise the components so that during production we can eliminate problems on an operative basis and thus avoid needless extra costs for projects. Production is effective and fast, and we deliver by the deadline.

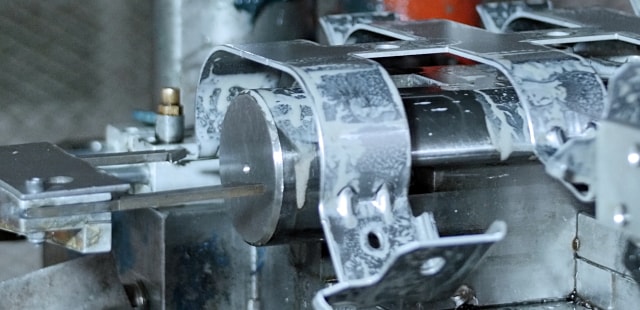

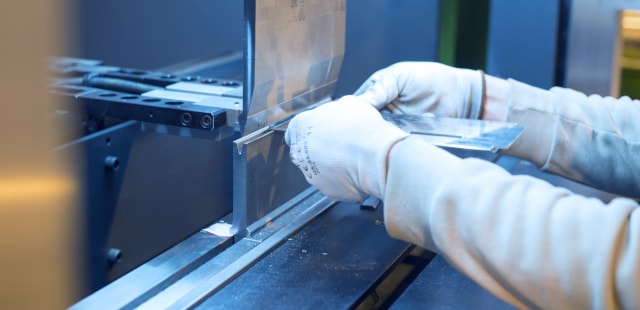

We use methods of punching and flat shaping of sheet metal on CNC machines. Based on supplied drawings we punch out complex shapes from sheet metal, which are then bent on CNC brake presses. The prepared products are then assembled using manual and robotic welding, riveting and other fastening elements.

We use zinc electroplating to add a zinc coat to materials (Zn and Zn/Ni), which serves as a base layer for further coating, or as a surface finish it gives products a more attractive appearance than in their unfinished state. In any case it fundamentally improves the mechanical and electrical properties of metals.

We protect the surface of your products from adverse environmental influences such as corrosion or UV radiation. Metal parts finished with powder coating in combination with cataphoresis and/or zinc electroplating (Lakum ensures duplex or triplex for you) become virtually immortal.

We enhance the quality of your products with an anticorrosion surface finish that is friendly in terms of environment and your budget. Cataphoresis is used as the basic protective layer for finishing electrically conductive materials. Combined with other types of surface finish - such as powder coating or zinc electroplating - you will give your products the highest possible resistance and life span.